Posted on 28 January 2020

Relieve the “Head-aches” of Distillation columns

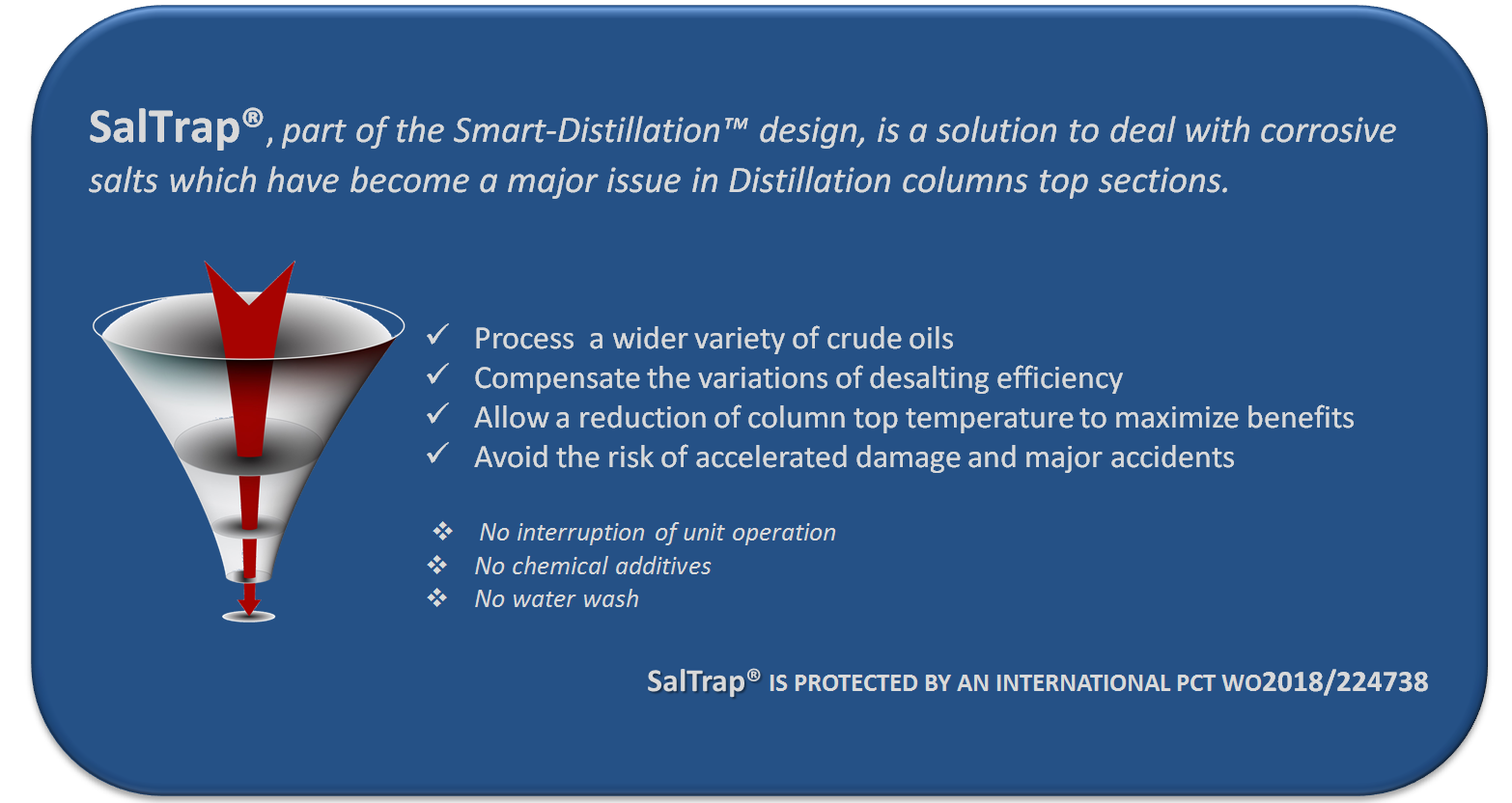

SalTrap® technology, part of Smart-Distillation™ design

SalTrap® is a new technology to protect the Top Sections of Distillation columns (CDU & VDU) against corrosive salts. These salts may be formed as a result of either higher salt content in desalted crude or column top temperature drop to maximize valuable products.

Why ?

The refining sector is facing major changes in the quality of the crude oils to be processed. It must adapt to the increasing share of so-called “opportunity” crudes. These crudes are generally more difficult to desalt, leading to increased salt contents of the desalted crudes. One of the effects induced by this evolution is the risk of formation of extremely corrosive chloride salts (HCl/Ammonia, HCl/Amines, etc.) in the columns. This risk is even more accentuated when the operating temperature of the columns is lowered in order to maximize valuable products. Once these salts are formed, the process equipment is severely attacked resulting in a major risk of detrimental damages which can lead to operation loss and/or accidents.

SalTrap®, makes it possible to eliminate the risk of damage in distillation units and downstream units by avoiding the entrainment and migration of these corrosive salts.

For who ?

All petroleum refineries processing “opportunity” crudes for the economic interest they represent, the ones facing desalting issues or the ones pushing distillation boundaries to increase yields. The vast majority of refineries is concerned because of their profit-driven strategies leading to:

- Maximizing the valuable products / distillates (operation optimization)

- Processing discounted / tougher crudes (operation flexibility)

How ?

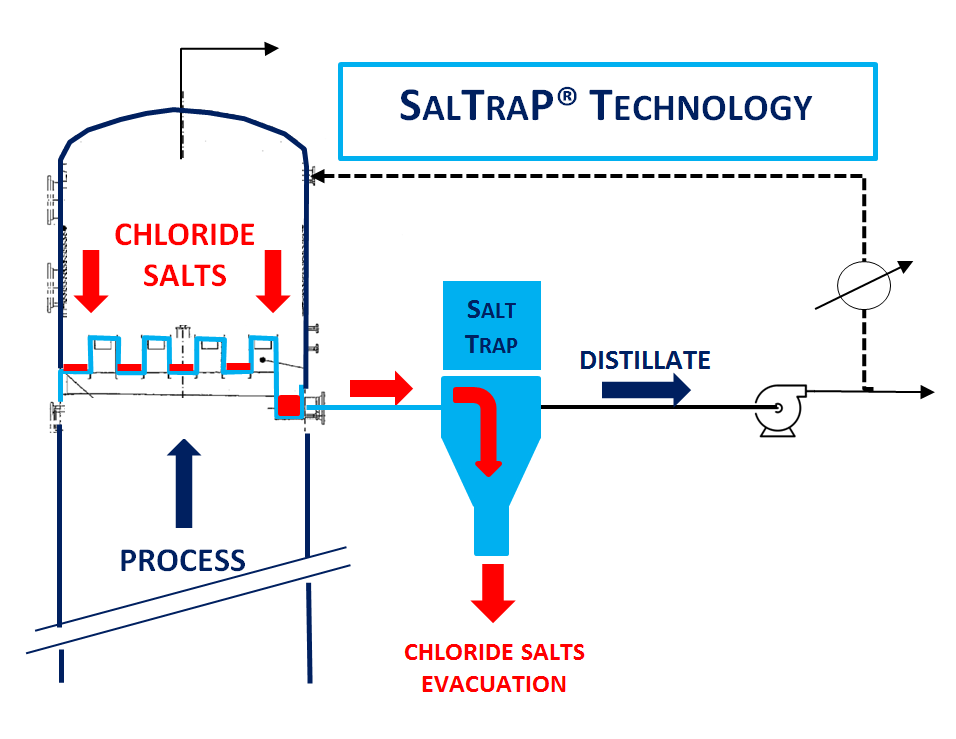

The principle of SalTrap® is based on the on-stream continuous entrapment, and withdrawal of the corrosive salts that may form during operation.

Entrap – Extract – Evacuate

It consists in removing chloride salts at the earliest opportunity before they could cause any damage or safety incident. SalTrap® applies to CDU and VDU. It shall be installed in the draw off system of the top section of the columns, as close as possible to the column.

It consists in removing chloride salts at the earliest opportunity before they could cause any damage or safety incident. SalTrap® applies to CDU and VDU. It shall be installed in the draw off system of the top section of the columns, as close as possible to the column.

Watch the video that illustrates the principle of formation, collection and evacuation of corrosive salts by SalTraP®.

Highlights:

This solution is adjustable to all crude oil distillation units and makes it possible to compensate the variations of desalting efficiency without impacting the production capacity of the unit. This technology can be implemented during the design phase (new units) or added to any operating unit. It therefore offers a real perspective to refineries and the opportunity to improve their margins by treating a greater variety of petroleum products on the market without exposing themselves to the risk of major damage.

Founding value :

SalTrap®, part of the Smart-Distillation™ design, is a solution to deal with corrosive salts which have become a major issue related to the evolution of the crude oil refining.

SalTrap® is protected by an International PCT No. WO 2018/224738 entered into National phase in Europe, USA, China, India and Brazil.

SalTrap® is an international trade mark

Smart-Distillation™ is an international trade mark

If you are interested by this technology: Contact us